Magnetic flow meters, also called mag meters, are widely utilised in a number of industrial field applications because of their reliable flow rate measurements and features like low pressure reduction and maintenance-free operation.

Magnetic flow meters, also called mag meters, are widely utilised in a number of industrial field applications because of their reliable flow rate measurements and features like low pressure reduction and maintenance-free operation.

Mag meter is ideal for wastewater applications, or any dirty liquid which is conductive or water based.

Accuracy over a wide flow range can be as good as ± 0.5% of flow rate or better.

Electromagnetic Flowmeter Technical Guide

Introduction to Magnetic Flow Meters Technology. How They Work & What Is It? Their applicaitons and use.

What are Electromagnetic Flow Meters?

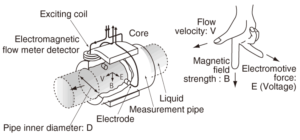

A magnetic flow meter (mag flow meter) is a volumetric flow meter. Electromagnetic Flow Meters do not have any moving parts. Magnetic flow meter is ideal for any dirty liquid which is conductive or water based, like: wastewater applications. Where low-pressure drop and low maintenance are required, Magnetic flowmeters are also idel.

A magnetic flow meter (mag flow meter) is a volumetric flow meter. Electromagnetic Flow Meters do not have any moving parts. Magnetic flow meter is ideal for any dirty liquid which is conductive or water based, like: wastewater applications. Where low-pressure drop and low maintenance are required, Magnetic flowmeters are also idel.

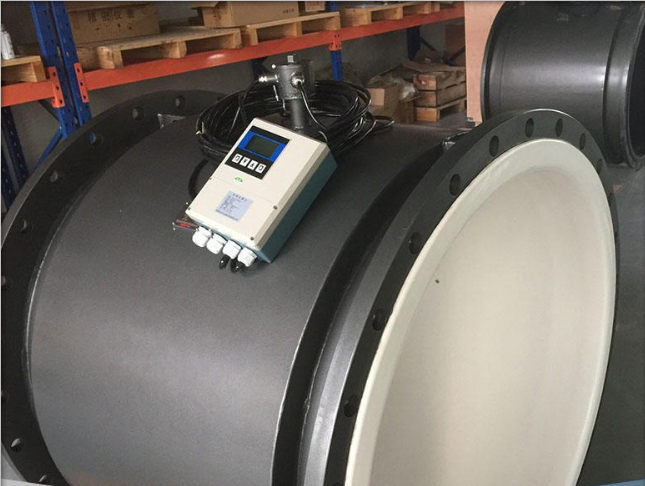

Magnetic flow meters are often selected and specified for applications, because they are obstruction-less, cost-effective for aggressive chemicals and slurries. Magnetic flow meters provide highly accurate volumetric flow measurement. Accuracy over a wide flow range can be as good as ± 0.5% of flow rate or better. Magnetic flow meters can be compact type, remote type, and insertion type. A wide range of liner materials, electrode options, and line sizes accommodate a wide variety of process application.

Application Cautions for Magnetic Flowmeters